Techflow Enterprises Pvt Ltd is one of the leading reliable suppliers of products such as pulse jet dust collectors for Crushing, bag houses, dust collection systems, air pollution control devices, dust collection systems, furnace smoke extraction systems, cassette filters and online purification. Bag filter, ESP, bag filter, ESP, silovent filter, air pollution control device, centrifugal fan and blower, fume emission control system, welded fume extraction system, air transportation system, fabric filter, offline cleaning bag filter, reverse air cleaning domestic Bag filter pulse jet dust collector for various industries outside.

We, Techflow Enterprises Pvt Ltd, have a lot of particle board manufacturing, kiln exhaust, cement, hot gas and fume, mining and minerals, boiler exhaust, coal treatment, air pollution control system, casting, steel, solids drying and much more. We have supplied equipment that is indispensable to the industry. Glass, woodworking and laminating and other industries.

Discover more| Dust Collector for Crushing Applications |

|---|

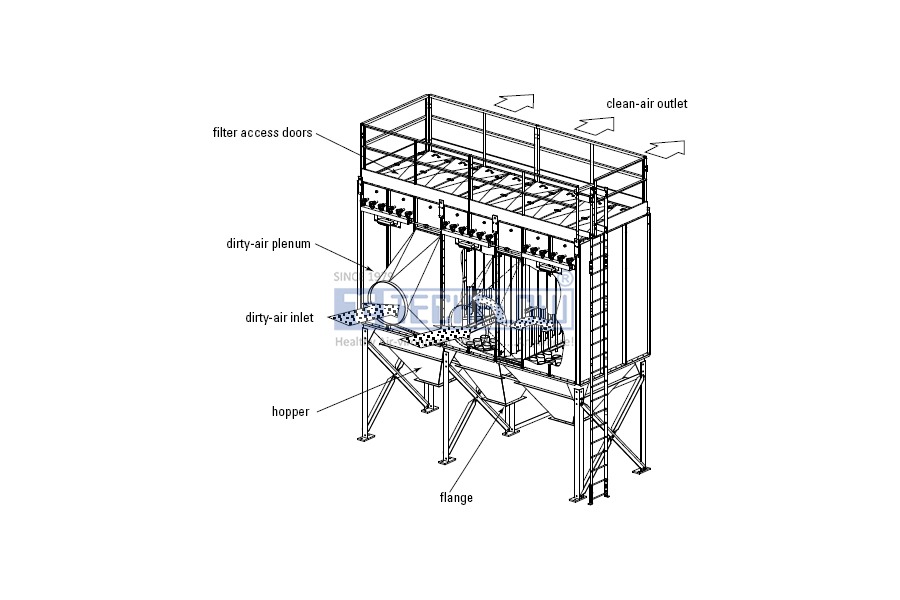

In a crushing pulse jet Dust Collector, used air flows through the cartridge, retaining dust molecules and leaving only clean, clean air in the environment. Cartridge pulse jet dust collectors for crushing have the advantages of compact structure and small footprint. |

This is the main reason why these systems are so widely used for destruction. Techflow offers a large combination of pulse jet precipitators for grinding in the range of 1000 CuM / h to 1,00,000 CuM / h. These cartridge filters work with additional spare parts and alternatives such as surface filtration technology, drainage equipment, and different fabrics for different applications. |

TECHNOFLOW designs and supplies highly efficient pollution control systems. These systems are known by many names at home and abroad. You can use pulse jet dust collectors for crushing, bag filters for boilers, dust removal systems, pulse jet bag filters, bag houses, bag filters, ESPs for boilers.

|

1. Online Cleaned Pulse Jet Dust Collector for Crushing

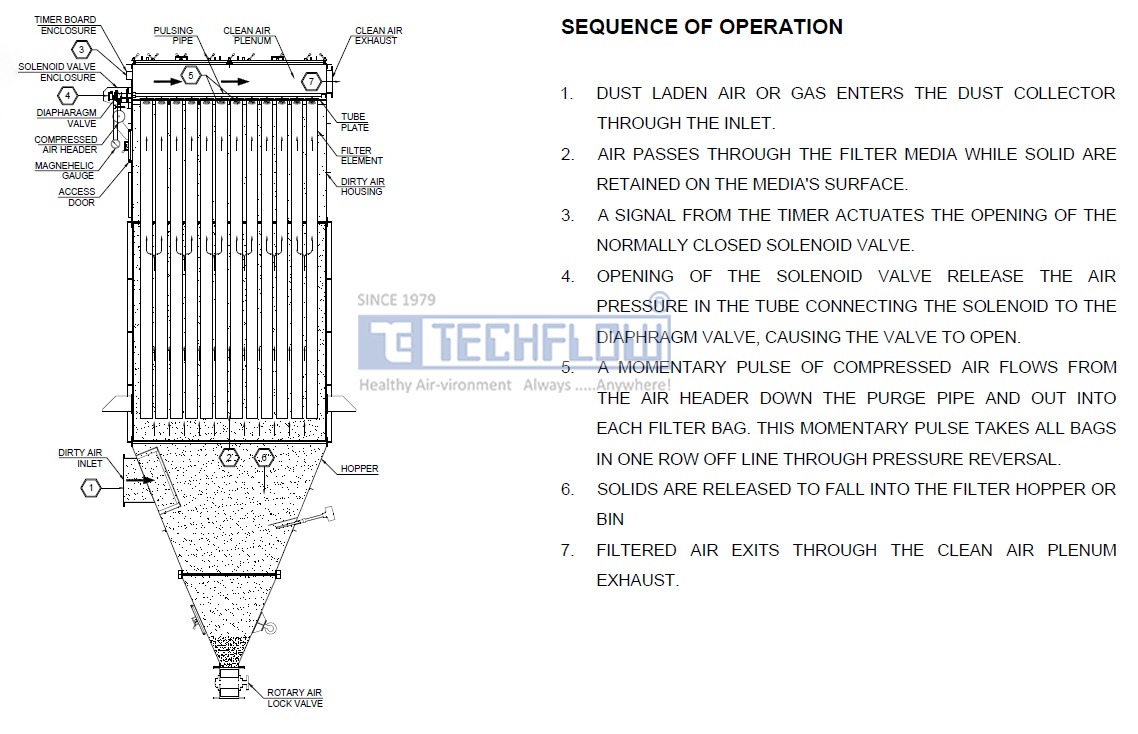

Dust-filled air enters the hopper, where heavy molecules fall out of the air stream. Heavy particles are trapped in the air and rise to the filter bag. When the purified air is discharged from the collector, it flows through the filter bag and collects dust particles on the outer surface. Blow tubes and pulses moved jets of compressed air through the venturi at precise intervals. This includes secondary airflow that is powerful and temporarily alternating through the pockets. The result is an internal shock wave that compresses and expands outward as the shock propagates its length. This process releases dust from the backflow of air on the surface of the bag and sinks it into a collection called a hopper. This technique switches the air flow in a series of bags, but only for a moment. This creates a continuous flow of air over the dust collector. The cleaning process is easy to set up and manage with solid-state timers. The differential pressure gauge allows and adjusts full control of the timer. To reduce the consumption of compressed air in the process, the pulse pause and duration can be set accurately and easily with a timer.

2. Off line Cleaned Pulse Jet Dust Collector for Crushing

It is also possible to split the pulse jet bag chamber. In this case, the gate / poppet valve on the clean air plenum regulates the passage of dirty air into the chamber. One of the two options is to install a separate pulse valve in each compartment that pressurizes the group of bags, or install a separate pulse valve that sends pulsating air directly to the blow tube outside the row of bags in the compartment. That is. During the cleaning process, the butterfly valve closest to the compartment blocks the flow of air. As part of the cleaning process, air is blown into the bag for approximately 2 seconds from the inlet of the impulse valve. The tray remains offline during the pulse process. The time frame may be shortened or extended based on the circumstances. After the insulation / poppet valve closes automatically, the chamber returns to flow. The alternative compartments are sequentially cleaned using a technique called "offline cleaning" until all bags in the bag house have been cleaned. The bag house consistently achieves much lower emission levels, but complete bag cleaning is possible, as is often the case with bag filters attached to low bulk products / dust.